First cleaning. I use a Dremel tool to spin clean bearings in Naphtha. Using mandrels to hold the inner race, the bearings and the outer race are free to spin. Here are some pics.

Bearing Tool Kit:

Mandrels:

I use plastic tubing of various sizes on the mandrel between it and the bearing to prevent the metal mandrel from contacting and scratching the bearing inner opening.

So, let's get some spools out and go to work...

Work Space (outdoors everyone):

Dremel Tool. It is easier to work with if you use a flex-shaft. (You"ll notice most everything is covered in the silver Tungsten Disulfide)

Naphtha. I use baby food jars.

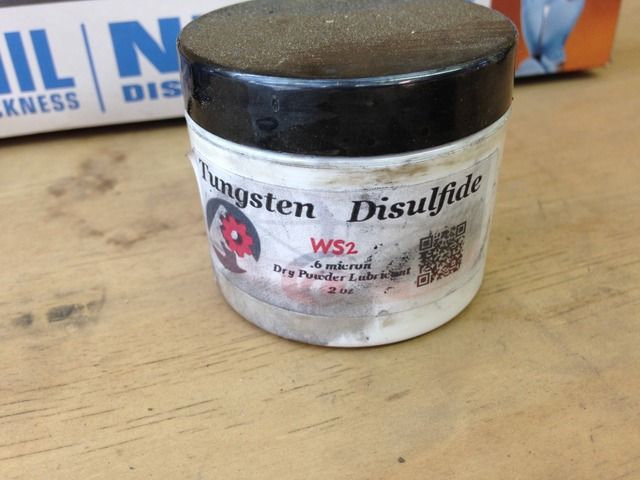

Tungsten Disulfide.

Secret Sauce.

Video of cleaning and application of Tungsten Disulfide.

https://youtu.be/yaRoov7SfYY

I have applied the Ws2 as a dry powder into the bearing and spun to apply which works. I tried using an air brush to spray while spinning, mixing the Ws2 with Naphtha, but it is too difficult to keep the Ws2 in suspension. Using the Naphtha/Ws2 mixture, about 25% Ws2 to 75% Naphtha and spinning until dry applies a nice coat to the bearing.

Once the Naphtha is spun out and the bearing is dry you should see silver flecks spinning out from the bearing. This is the excess Ws2. Tungsten Disulfide will not stick to its self. You will get a single molecule thick coating of about 3 microns.

I run my bearings dry with this coating and get great performance. I reapply once a year. Occasionally when spinning a bearing all of the excess Ws2 does not get ejected and you do not get a smooth rotation on the bearing. If this happens, a quick spin back in the naphtha will clear it out.

I have worked with stock Daiwa bearings, removing the shields and it is amazing how much the quality varies. Some I clean and apply the Ws2 and get almost no improvement but some will perform as good as ABEC 7 bearings when the Ws2 is applied.

Hope you enjoyed and hopefully this helps those of you crazy enough to put in this much effort for little green fish.

Doug